Free 2 Day Domestic

Free 2 day shipping for all domestic orders. Free Expedited shipping for all international orders over $399.

Due to Microsoft's discontinuation of updates, including security, certain functionality such as checkout and CAD may not work for you. We recommend using Google Chrome, Microsoft Edge, Firefox, or Safari to ensure full functionality.Thank you - the Ruland team

| Dimensions | |||

|---|---|---|---|

|

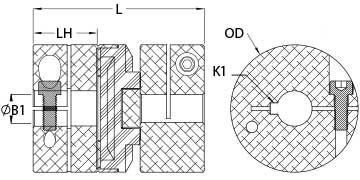

Bore (B1) Larger inner diameter. Should match nominal shaft diameter. |

11 mm |

Keyway (K) |

4 mm |

|

Outer Diameter (OD) |

1.313 in (33.3 mm) |

B1 Max Shaft Penetration The maximum depth the shaft can penetrate into Bore B1. |

15.0 mm |

|

Bore Tolerance Variance in finished bore range before installation. |

+0.03 mm / -0.00 mm |

Hub Width (LH) |

15.00 mm |

|

Length (L) |

1.875 in (47.6 mm) |

Recommended Shaft Tolerance Acceptable variance in nominal shaft diameter before performance loss. |

+0.000 mm / -0.013 mm |

| Fastening Hardware | |||

|

Forged Clamp Screw Inch or metric socket head cap screw size. |

M3 |

Number of Screws |

1 ea |

|

Screw Material |

Alloy Steel |

Screw Finish Surface finish and treatments on supplied hardware. |

Black Oxide |

|

Seating Torque Torque required to install supplied hardware. Use torque wrench for accurate seating torque. |

2.1 Nm |

Hex Wrench Size Wrench size that fits the screw head to tighten or loosen the screw. |

2.5 mm |

| Performance Specifications | |||

|

Torque Specifications Torque is dependent on the insert selected. Please see "Recommended Inserts" to select the correct insert for your application. |

Torque ratings vary with insert selection |

Angular Misalignment Max angle of the shaft axes relative to each other. |

0.5° |

|

Parallel Misalignment Shafts are parallel to each other, but not in-line with each other. They are offset. |

0.008 in (0.20 mm) |

Max Parallel Misalignment Oldham couplings can exceed the standard parallel misalignment rating without additional bearing loads. When using at the max rating, life cycle of the insert may be impacted. The user must test for suitability. |

0.131 in (3.33 mm) |

|

Axial Motion The amount shafts can move closer to or away from each other. This is meant for thermal expansion of the shafts. No axial force can be placed on the coupling. |

0.006 in (0.15 mm) |

Moment of Inertia |

5.286 x 10-6 kg-m2 |

|

Maximum Speed |

4,500 RPM |

Recommended Inserts Any of these inserts will match this coupling hub. |

|

|

Full Bearing Support Required? Full bearing support is a bearing in close proximity to both sides of the coupling to prevent axial loads that could result in rapid coupling failure. |

Yes |

Zero-Backlash? Zero-backlash ensures there is no loss of motion during operation. |

Yes |

|

Balanced Design The balanced design allows for reduced vibration at high RPMs. |

Yes |

Mechanical Fuse? The disc is designed to break at a certain torque. When it reaches the torque, it breaks and power transmission stops. |

Yes |

| Additional Information | |||

|

UPC |

634529208281 |

Country of Origin |

USA |

|

Material Specification |

2024-T351 Aluminum Bar |

Finish |

Black Anodized |

Sulfuric Anodized MIL-A-8625 Type II, Class 2 and ASTM B580 Type B Black Anodize |

Manufacturer |

Ruland Manufacturing |

|

|

Temperature Minimum and maximum operating temperature. Operating temperature includes ambient temperature plus or minus factors such as system heat generated during operation, washdown, vacuum, etc... |

Acetal Disk -10°F to 150°F (-23°C to 65°) |

Weight (lbs) |

0.073600 |

|

Tariff Code |

8483.60.8000 |

UNSPC Code used to identify products to standardize nomenclature around the world. |

31163015 |

| Product Notes | |||

|

Note 1 |

"Now available in stainless steel!" |

Note 2 |

"Performance ratings are for guidance only. The user must determine suitability for a particular application." |

|

Note 3 |

"Torque ratings for the couplings are based on the physical limitations/failure point of the torque disks. Under normal/typical conditions the hubs are capable of holding up to the rated torque of the disks. Please consult technical support for more assistance." |

|

|

| CERTIFICATIONS/STANDARDS | |||

|---|---|---|---|

| ISO 9001:2015 | Conflict Minerals | ||

| RoHS3 | REACH | ||